LOPO’s cooperative factory in Bangladesh

The process of manufacturing:

The most interesting and promising part of our product is the clay itself. This is special because it is only available in our locality from all over the country. Our craftsmen, the genius souls, doing this from long generations, are the most integral part of our business.

It starts with selecting the clay from the paddy lands. We extract it by digging 2-4 feet down and then mix it carefully.

Image 1.1- Craftsman collecting Clay from paddy land.

Afterwards, we add appropriate amount of water and make pieces with perfect consistency until it is perfectly suitable to be fit in the wooden mould.

Image 1.2 – Women craftsmen making pieces with wooden mould

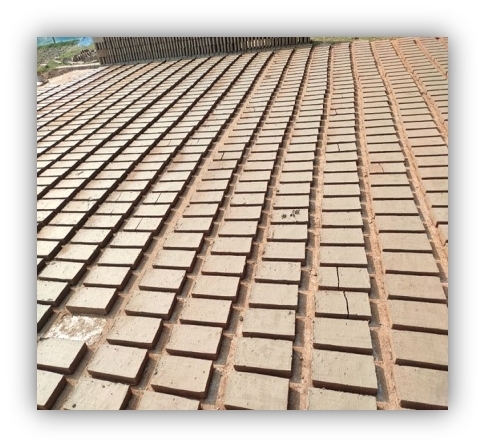

Craftsmen make each pieces individually with their magical touch of hand only and then put those in the ground for 3/4 days. Thus allowing those to be cured and dried by the sun and wind.

Image 1.3 – Tiles and bricks are being dried and cured in the sun and wind.

When pieces are ready to fire, we put those very carefully in special kilns, designed by us, in a proper manner. For the firing purpose, we use trees, planted simultaneously time to time, by us, as fuel.

Image 1.4 – Pieces are ready for fire

Image 1.5- Special Kiln design by us

Burning those at 900-1100 degree Celsius for almost 90-95 hours makes it stronger than ever. Thus each piece comes out with magnificent shape and color.

Image 1.6- Tiles and Bricks after firing in the Kiln

Image 1.7- Finished Products

Image 1.8- Products ready for Export