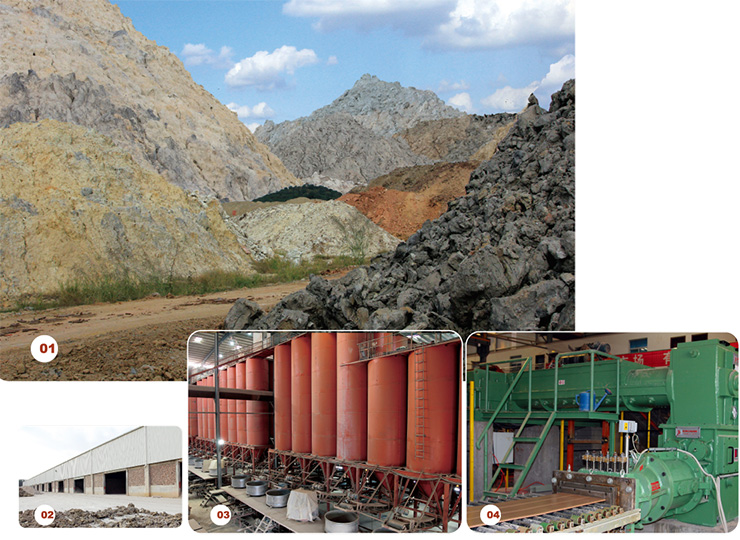

LOPO focus source and technology, starting from the raw material, efforts to control the details of each process, ensure that each pieces of terracotta panels / terracotta tiles with high quailty.

LOPO Terracotta Corporation has world class production lines and equipments, imported from Italian and localized by ourselves, of which are strong production capability with annual production of 4,500,000 sqm Clay Tiles, 600,000 sqm Cultured Stone and 1500,000 sqm Terracotta Facade Panels. Every indicator of energy consumption has reached the leading level. (Facilities)

Production line characteristics

– 80,000 square meter of open-air stocking yard, natural clay raw materials stock quantity is 300,000 tons

– Reserves of 150000 tons indoor storage bin

– Reserves of 12000 tons mud materials storage system

** The large capacity reserve of raw materialsensure the stable quality of products;big quantity orders are available for quick delivery requirement.

– Italian advanced molding equipment

** Extrusion molding stable, prevent bad product phenomenon inside, such as cracking, uneven thickness and so on.

– Drying slowly in 80m high kiln with five layers

** Enough time and space for dryingmakes semi-finished panels optimization; In addition, the large capacity of green-brick storage system can guarantee the main kiln operate stable.

– Domestic longest roller kiln (260 meters) with 428 firing units

** The longestroller kiln, to ensure product quality.

– Automatic cutting and edge grinding machine

** Reduce artificial elements, efficiency, ensure product sizeconsistency.

We are committed not only to the development of our company but also the responsibility of our society and environment. We will put our greatest effort to harmonize our mutual home with green products.