Malaysia Terracotta Panel & Terracotta Baguette Project | Architectural Terracotta Facade

This project utilizes high-quality terracotta panels and baguettes, enhancing the modern aesthetic and durability of the architectural facade.

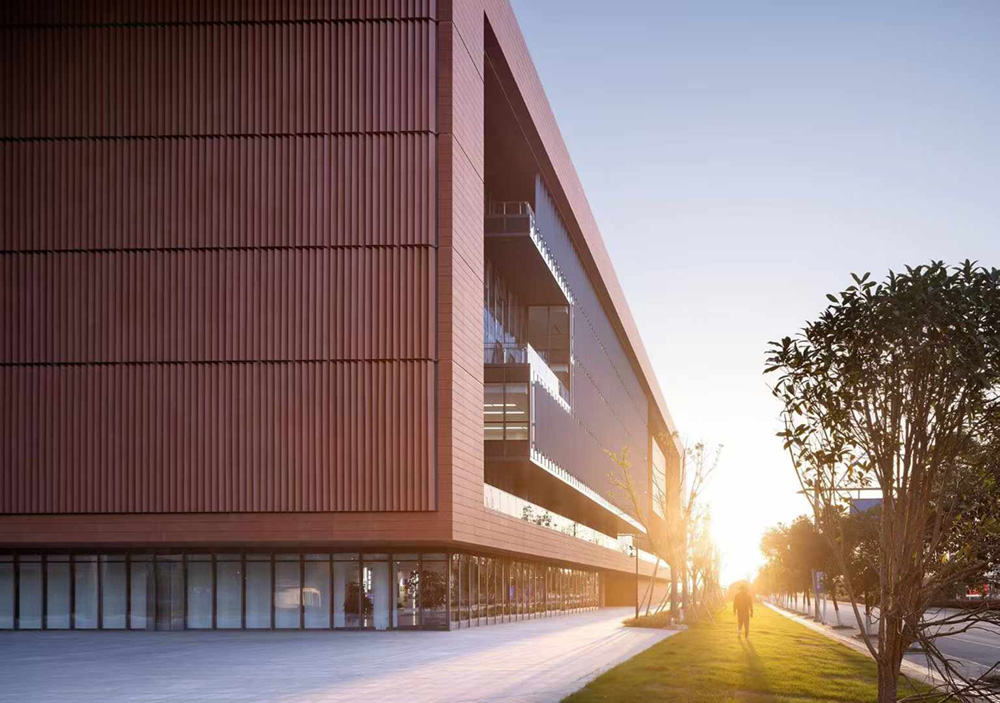

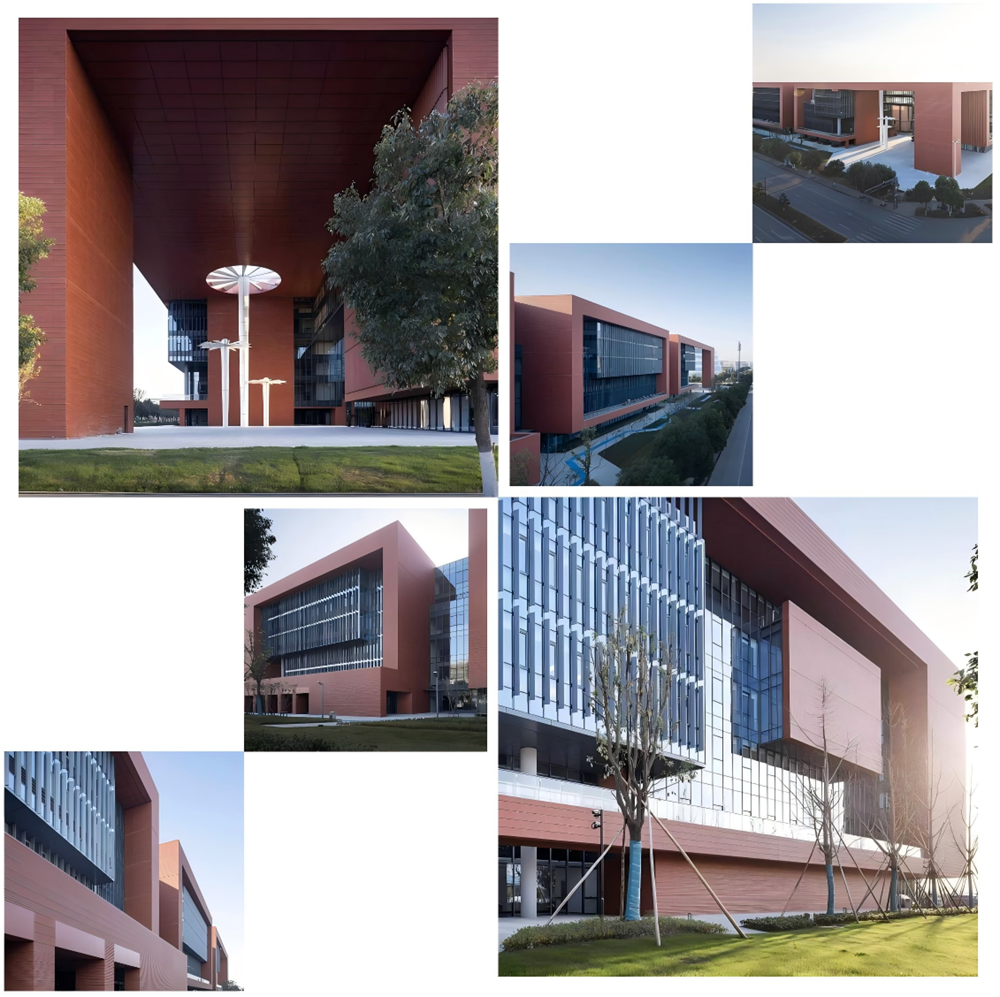

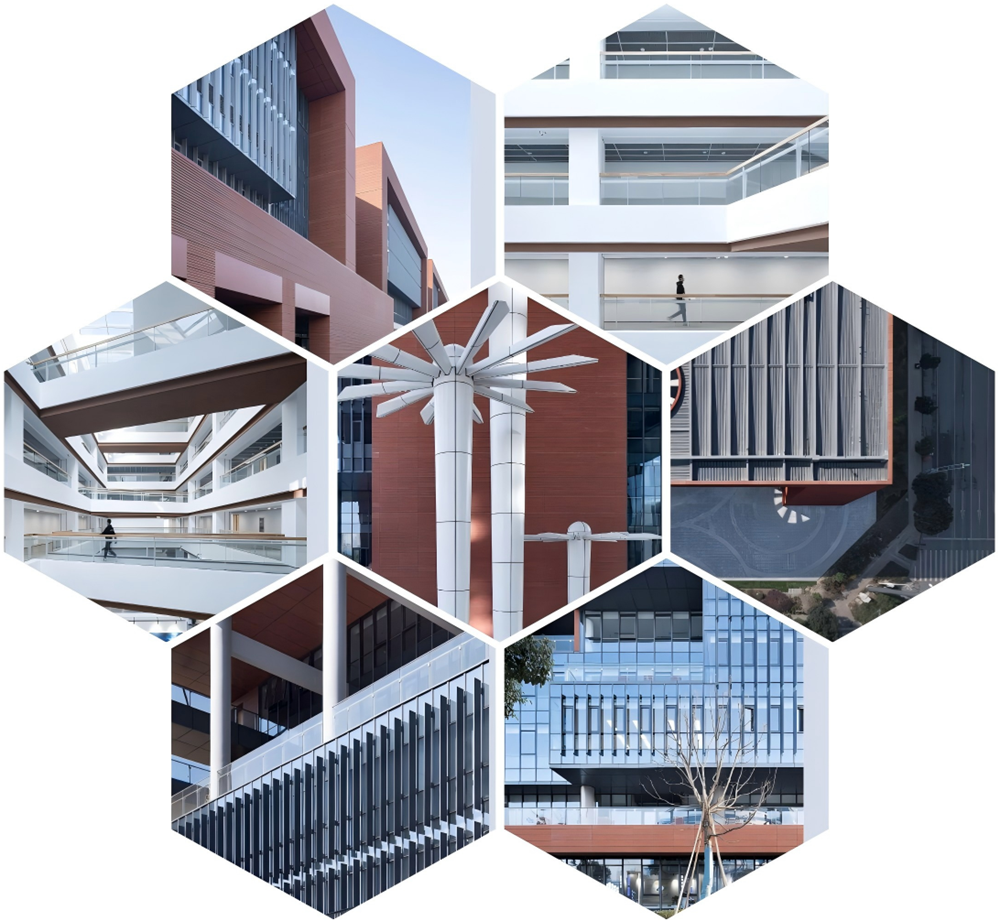

The construction of the Penang Innovation Hub marks a breakthrough in modern engineering, combining advanced materials with efficient building practices. At the heart of its design is the innovative use of modular terracotta facade panels, supplied by LOPO Terracotta. These panels not only enhance the building’s aesthetic but also play a critical role in optimizing construction efficiency and meeting the challenges of Penang’s tropical climate.

01 Modular Installation for Increased Efficiency

One of the defining features of the Penang Innovation Hub is its modular facade system. The terracotta panels were designed with precision and uniformity, allowing for seamless installation. The modular approach brought several key benefits:

- Faster Construction Timelines: The pre-fabricated panels required minimal on-site adjustments, reducing installation time significantly.

- Cost-Effective Workflow: The modular system minimized waste and labor costs, ensuring that the project stayed within budget without compromising quality.

- Improved Safety: Pre-fabrication allowed much of the work to be completed off-site, reducing on-site risks and streamlining the construction process.

The simplicity and accuracy of the modular installation made the terracotta facade system an ideal choice for a project of this scale, ensuring timely completion without sacrificing craftsmanship.

02 Addressing Climate Challenges with Terracotta

Penang’s tropical climate, characterized by high humidity, heavy rainfall, and intense heat, posed significant challenges during the construction and design phases. The selection of terracotta panels was critical in overcoming these environmental factors:

- Moisture Resistance: The terracotta panels are inherently water-resistant, preventing moisture infiltration that could damage the structure over time.

- Thermal Insulation: Terracotta provides excellent thermal performance, helping to regulate indoor temperatures and reduce the reliance on air conditioning, making the building more energy-efficient.

- Durability in Extreme Conditions: The panels are engineered to withstand Penang’s heavy rains and high temperatures, ensuring long-term durability and low maintenance costs.

The use of terracotta not only addressed these climate-specific challenges but also enhanced the overall sustainability of the project.

03 Green Construction Practices

In line with the global push for environmentally responsible construction, the Penang Innovation Hub adopted green practices throughout its development:

- Dust and Noise Control: The modular terracotta panels minimized on-site cutting and processing, reducing dust and noise pollution in the surrounding areas.

- Reduced Waste: Pre-fabrication of the panels ensured precise measurements and minimized material waste during construction.

- Sustainable Materials: LOPO’s terracotta panels are made using eco-friendly manufacturing processes, contributing to the building’s green credentials.

These practices aligned with the project’s goal of creating an environmentally sustainable landmark that sets a benchmark for future developments in Malaysia and beyond.

04 Technical Highlights of the Facade System

The terracotta facade system at the Penang Innovation Hub stands out for its technical precision and adaptability:

- Ventilated Facade Design: The panels create a ventilated gap between the exterior and the building’s core, improving airflow and reducing heat buildup.

- Customizable Panel Layout: The modular system allowed for creative design flexibility, enabling architects to achieve a distinctive look while maintaining structural integrity.

- Low Maintenance: Terracotta’s natural durability ensures minimal upkeep, reducing lifecycle costs for the building owners.

This combination of technical innovation and aesthetic appeal ensures that the Penang Innovation Hub is both a functional and visually striking addition to George Town’s skyline.

05 Conclusion: A New Standard in Sustainable Construction

The Penang Innovation Hub exemplifies how advanced materials and efficient construction techniques can overcome environmental challenges and deliver exceptional results. The use of LOPO Terracotta panels played a pivotal role in achieving the project’s goals, from enhancing sustainability to improving construction workflows.

As a model for future developments, this project demonstrates the potential of modular facade systems to transform modern construction, creating buildings that are not only beautiful but also environmentally and economically sustainable.

This project demonstrates the extensive application of terracotta panels in modern architecture, improving the overall visual appeal of the building.

Malaysia Terracotta Panel & Terracotta Baguette Project | Architectural Terracotta Facade