Exterior facade terracotta panels are a type of cladding material made from natural clay, which is fired at high temperatures to create a durable, weather-resistant, and aesthetically pleasing finish for building exteriors. These panels have gained popularity in modern architecture due to their eco-friendly nature, energy efficiency, and versatility in design.

There are more and more materials replacing natural stone, such as coatings, insulation coating integrated panels, quartz porcelain plate, etc. In the previous issues, we introduced new materials that can replace stone.

Translation: Imitation Stone Coating: Creating the Effect of Stone with Coatings – Performance, Process, and Cost of Exterior Wall Products.

Today, we are introducing a new material for exterior wall decoration – Exterior Facade Terracotta Panels. Since the first terracotta panel project was completed in Munich, Germany in 1985, it has a history of more than 30 years. Its unique charm has won the love of architects, and it has been widely used in various types of buildings for its unique appeal.

Terracotta panels are a new and popular facade material in the construction industry today. They are installed through dry-hanging, which allows for easy replacement and offers a flexible solution for external facade design, benefiting urban beautification and the livability of buildings.

-01-

Constitute | Category

Exterior Facade Terracotta Panel is mainly made of natural clay as the primary material, with a small amount of other ingredients such as quartz, pumice, feldspar, and pigments added. The panel is formed by molding the flowing clay slurry with a mold.

Terracotta Panel Product Classification

In terms of structure, clay curtain wall products can be divided into single-layer terracotta panels, double-layer hollow terracotta panels, terracotta rods, and terracotta louvers. In terms of surface effects, they can be divided into natural surface, sandblasted surface, grooved surface, printed surface, corrugated surface, and glazed surface. The hollow design of the double-layer terracotta panel not only reduces the self-weight of the clay panel but also improves its air permeability, sound insulation, and thermal insulation performance. Single-layer terracotta panels, also known as solid terracotta panels, are used when the bearing capacity requirements are low and are relatively less used in practical engineering. They are mainly used for local decorative building walls with low requirements. Its characteristics are that there are no cavities, and the cross-section is a solid body. The regular thickness is 20-30mm, the board width is 150-600mm, the maximum board length is 1200mm, and the unit weight is 45-65kg/m².

Double-layer hollow terracotta panels: one of the most common forms of terracotta panels used in building curtain walls. It has high load-bearing capacity, light self-weight, and the hollow internal structure helps to improve energy-saving and sound insulation performance. The surface of the plate can be made into various personalized textures and color combinations according to design requirements.

Terracotta rod and louver: Terracotta rod and terracotta louver are important types of terracotta plate products with wide applications. There are various cross-sectional types to choose from, such as square, rectangular, circular, triangular, and diamond, and many installation methods are available. They can be used as exterior sunshade devices for curtain walls to reduce direct sunlight and improve the comfort and aesthetics of the building. They can also be used for interior decoration to add artistic flavor to the building.

Specifications of Exterior Facade Terracotta Panels

They can be cut to any size to meet different installation needs and fulfill the requirements of various architectural styles.

Standard Exterior Facade Terracotta Panel products are divided into four categories based on thickness and cross-sectional shape:

40mm thick hollow large panels; 30mm thick hollow medium panels; 20mm thick hollow small panels; 15-20mm thick solid panels.

Standard lengths are 300mm, 600mm, 900mm, 1200mm, 1500mm, and 1800mm, while standard widths are 200mm, 250mm, 300mm, 450mm, 500mm, 550mm, and 600mm.

The color of the terracotta panels can be the natural color of the clay after high-temperature firing, usually consisting of three-color series: red, yellow and gray. The color is very rich, which can meet the requirements of architects and owners for the color selection of building exteriors. The color is lustrous, gentle and attractive, with good durability. The natural texture and timeless clay color of the terracotta panels greatly arouse the interest of owners and architects.

-02-

Performance

| Comparison between Exterior Facade Terracotta Panel and Dry Hanging Stone Materials | ||

| Index | Terracotta Panels | Stone Materials |

| Conditions for Formation | Compression under pressure of 7200T; firing at high temperature of 1250 degrees Celsius. | Generation under natural conditions. |

| Dead-weight | 70-76 KG/m^2 | 75-85KG/m^2 |

| Slab Weight | 25KG/m^2 | 60-80KG/m^2 |

| Slab Thickness | ≥12mm | Granite(marble) above 25(35)mm |

| Modulus of Rupture | ≥30mpa; ≥27mpa(minimum) | ≥8mpa |

| Water Absorption | ≤ 0.5% | 1%-7% |

| Color | Glazed on the surface, with rich colors and basically no color difference. | The color is affected by the natural color of the rough material, resulting in significant color differences. |

| Noise Reduction | Bad | Fair |

| Durability | Not easy to fade | The panel is prone to contamination, discoloration or fading. |

| Fire-resistance | A1 | A1 |

| Anti seismic property | Brittle materials, poor toughness, back-bolt hanging system, easy to fall off. | Manual grooving is common and prone to cracking and edge collapse. |

| Acid and alkali resistance | UA Class | Granite is resistant to acids at class B level, but is not resistant to alkalis;

Marble is alkaline-resistant at level B, but it is not acid-resistant. |

| Radiance | radioactive | The radiation is severe, mainly due to radon element. |

| Energy-saving | Solid structure is not conducive to energy conservation. | Solid structure, poor insulation, not conducive to energy saving. |

| Dry-hanging | Fragile materials, with easily broken rear bolt holes and a higher rate of surface material damage. | The commonly used methods for manual grooving and drilling are short-grooving and back-bolt type, but their accuracy is not high and it is easy for the stone to be improperly installed. |

Comparison between Terracotta Panels and Dry-hanging Stone Materials: Terracotta panels are a new type of building material that is environmentally friendly and made from natural clay and quartz sand. They are formed through extrusion and high-temperature firing, without any radiation, and have good durability and can be recycled.

- Through the test of time, the color remains true to the natural clay and maintains its natural, bright, and even hue without fading. It is durable, giving the curtain wall long-lasting vitality.

- Hollow structure is lightweight and provides thermal insulation by increasing thermal resistance. Terracotta facade panel are lighter in weight and simpler in design compared to stone curtain walls, resulting in cost savings in curtain wall installation.

- It is easy to clean, which is remarkable due to the stable physical and chemical properties of the terracotta cladding panels, as well as some special surface treatments. It has the functions of acid and alkali resistance and anti-static, so it will not absorb dust. In addition, it follows the principle of equal pressure rain curtain, and any dirt that is not decomposed will be washed away by the rainwater, ensuring the original color and texture are maintained forever.

- It possesses high performance, stable technical capabilities and strong impact resistance, meeting wind load design requirements for curtain walls. It has high temperature resistance, strong frost resistance and good flame retardancy, making it safe in the event of a fire. It also boasts a high aesthetic value, with a gentle appearance that can be easily combined with glass and metal. The warm and mild color of the clay curtain wall increases the cultural atmosphere of the building itself.

-03-

Technique

Terracotta Panel Production Technology:

Terracotta Panel production process:

Exterior Facade Terracotta Panel is mainly made of natural clay, with a small amount of other ingredients such as quartz, pumice, feldspar, and colorants. They are formed by high pressure extrusion, low-temperature drying, and high-temperature firing at 1200℃. Terracotta panel is environmentally-friendly, radiation-free, has a warm color, and do not cause light pollution. Due to thermal expansion and contraction during firing, there may be size differences. After high-precision mechanical cutting and inspection, they can be supplied to the market.

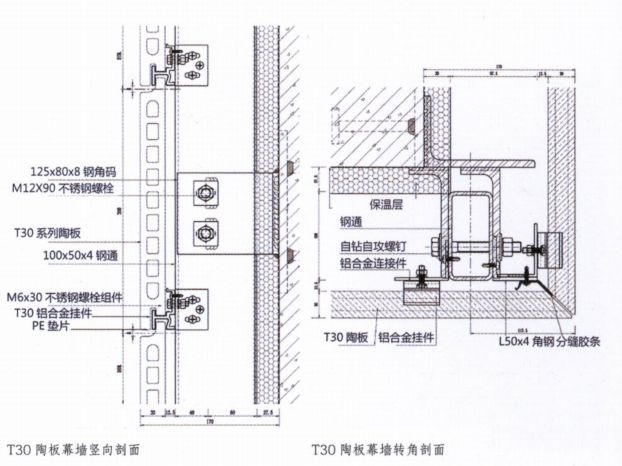

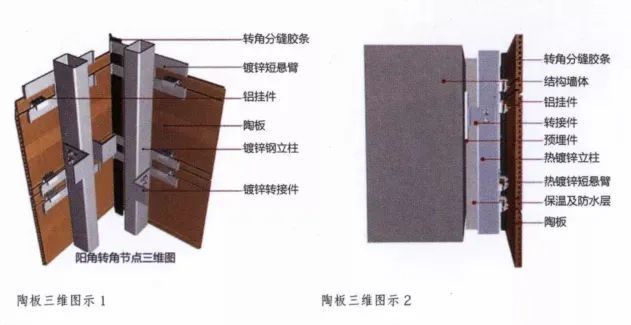

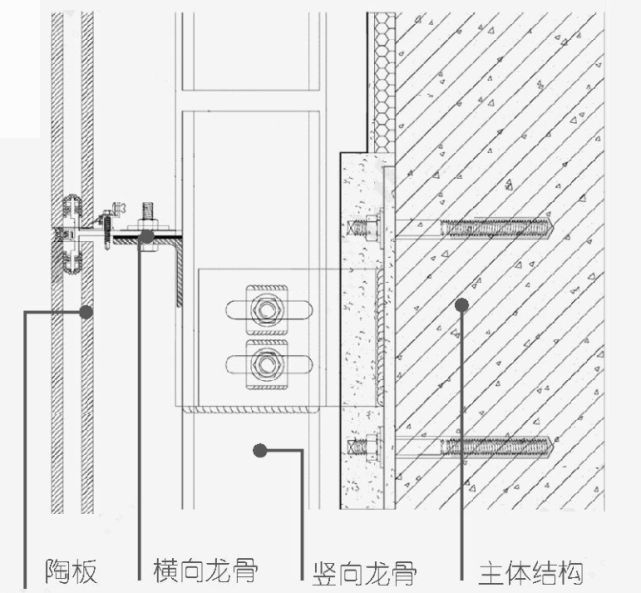

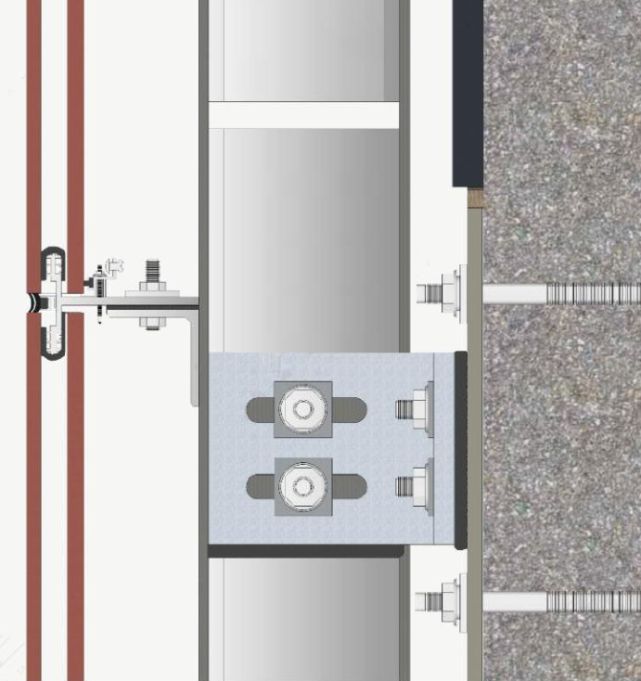

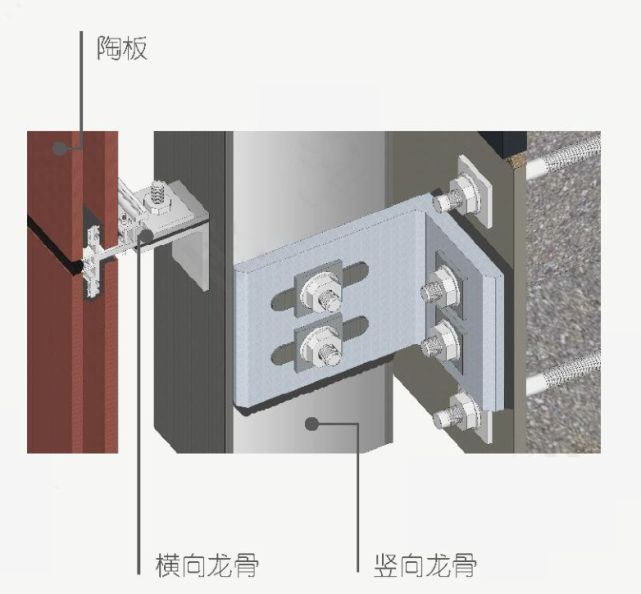

Terracotta curtain wall construction technology

Terracotta products are mainly formed by wet extrusion. According to different surface treatment technologies, terracotta can be divided into glazed terracotta and unglazed terracotta. Most of the products are unglazed natural textured terracotta. Glazed terracotta is a layer of glass body glaze applied to the surface of terracotta, which is glossier and more similar to common ceramic vessels. Some construction projects also use it.

The installation methods of terracotta cladding panel can be divided into two systems: open and closed.

- Open system: the panel joints are designed according to the equal pressure rain screen principle, and there is a waterproof sealing strip, which has excellent waterproof function. Sealing glue is not required at the joints to avoid contaminating the terracotta panels and affecting the appearance.

- Closed system: Using special sealing glue for tile joints, the waterproof function of the system can be better guaranteed. The closed air layer formed behind the tiles has better insulation and energy-saving effects.

Installation Diagram: Consistency between Terracotta Panel Physical Parameters, Specifications, and Calculation Documents.

- Compliance of the appearance and construction drawings of the terracotta panel, and the specifications of the Exterior Facade Terracotta Panel (referring to the specifications for metal and stone curtain walls);

- Acceptance of the supporting system (referring to the specifications for metal and stone curtain walls);

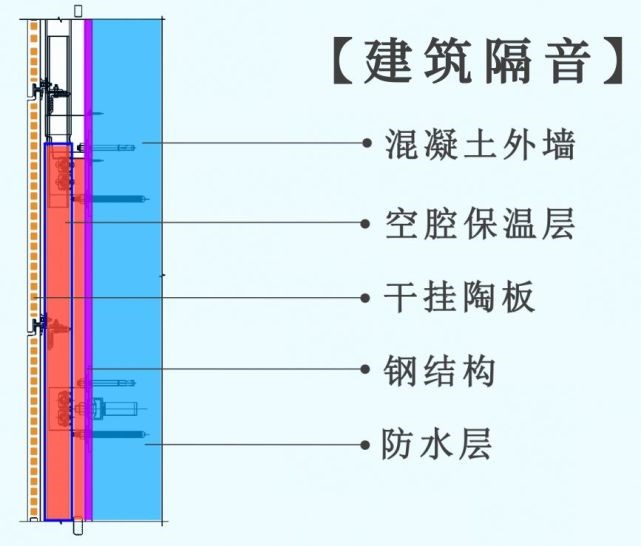

- Auxiliary functional acceptance (such as fireproofing, waterproofing, sound insulation, thermal insulation, earthquake resistance, etc.);

- Material qualification certificate, test report, embedded component pull-out test, and four performance tests of the entire system and so on.

-04-

Application case

The exterior of residential buildings, such as Longhua Jinmao Mansion, uses dry-hung terracotta panels, with a total of approximately 150,000 pieces of terracotta panel covering an area of nearly 70,000 square meters. The entire building uses dry-hanging technology to solve the problem of lack of load-bearing points on the exterior walls. Longhua Jinmao Mansion has constructed steel frames embedded in the walls and mobilized “super workers” from all over the country to ensure that the circumference error of each cut terracotta panel is no more than 2mm to ensure the smooth and seamless combination of the Exterior Facade Terracotta Panel on the building.

Shenzhen Longhua Jinmao Mansion Real Shot Image. The exterior wall of Jinmao Mansion is made of sound-absorbing terracotta panels, and the insulation layer and sound insulation effect are even better.

Exterior elevations of Huaruncheng Runfu, Shenzhen, show that the main materials used in the facade are off-white terracotta panel and dark grey aluminum alloy, creating a strong contrast in color that is simple, generous, fashionable and modern.

The exterior of Shenzhen Huarun Chengrunfu is depicted in a realistic image, while ARQ Architecture Firm used GRC and terracotta panel materials to create soft, curved shapes on the facade of the Lujiazui Zhongxin Nine Mansion project. This integration not only enhances the profile of the building, but also presents a unified and harmonious landscape through the ripple effect.

In the façade design of Zhongxin Ninth Mansion in Lujiazui, beautiful terracotta panels are installed in areas that may generate unfavorable sightlines, and decorative louvers are used to guide sightlines, opening up advantageous sightlines while shielding unfavorable ones. ARQ architectural firm has applied streamlined design to regularize fragmented facades in residential buildings.

Lujiazui Zhongxin Jiu Lu and Zhengzhou Yongwei Shanghe Jun’s exteriors are made of terracotta panel which not only add to their artistic beauty, but also adhere to the urban green and environmentally-friendly concept.

Zhengzhou Yongwei Shanghe Jun terracotta Façade

The façade of terracotta panel of Shanghe Jun in Zhengzhou Yongwei.

Real photos of the terracotta facade of the first phase of Zhengzhou Yongwei Shanghe Jun and the terracotta panel

The architecture of Zhongliang Jimo Shiguang Mancheng is a modern and concise form of interspersed design, primarily using perforated aluminum panels and red terracotta panels. The material of the red terracotta panel is mainly inspired by the traditional red roofs of Qingdao.

Real Scene Picture of Zhongliang Jimo · Shiguang Mancheng

The real-life image of Zhongliang Jimo Shiguang Mancheng shows the exterior of public buildings. The Wenzhou Vanke Center building is composed of differently sized volumes interweaving with each other, and the facade is made of materials such as glass, aluminum panels, and terracotta panels. The solid terracotta panel corresponds to the needs of large commercial spaces, while the virtual glass curtain wall and the half-solid, half-virtual printed glass correspond to the different requirements of small functional shops.

Wenzhou Vanke Center Architectural Photography: Qiu Ripei, Zhou Qi

The Terracotta panel has texture and the color is selected as beige, which adds some warmth to the facade with silver-white and blue-gray as the base tone. The use of vertical terracotta rods not only solves the problem of air conditioning exhaust, but also adds richness to the terracotta panel modeling.

Wenzhou Vanke Center, architectural photography by Qiu Ripei and Zhou Qi. The exterior of the Hunan Art Museum extensively utilizes red glazed terracotta panels, producing a wondrous color effect through spatial relationships in light and shadow. The glazed surface is influenced by sunlight, resulting in a rich and warm transition of color on the red terracotta panels. Even the texture of the façade can change with the variation of light.

Photography by ACF Field Visual. From a distance, the white block of the Hunan Art Museum appears in a folded, vertical shape resembling traditional Chinese painting paper. Upon closer examination, the glaze surface reveals a fine web of hidden ice-like fractures. The glossy surface reflects vivid hues from the surrounding environment, lending the white mass a range of subtle depth and changing colors. Interweaving lines of red merge and diverge to form an architectural blend of strength and softness, negative and positive space.

Hunan Museum of Art. Photography: ACF Realm Visual.

Led by Ma Yansong, MAD Architects released the Jiaxing Civic Center, designing a landscape architecture in a park. The waterside building overlooking the central park is covered with locally produced white terracotta panels, echoing the traditional tubular roof of the water towns in Jiangnan while also being more economical and energy-efficient.

The traditional tile roof of Jiangnan (left) and the white terracotta panels roof of the Jiaxing Civic Center (right).

The main facade of a health center in Italy features a completely transparent accessible space, with exterior wall panels made of clay for high-quality elasticity and support. Silk-like coatings are added to the terracotta panels for an astonishing white luster effect.

Daniele Domenicali

The exterior walls of a hospital in Manchester, UK are covered with glazed white terracotta panels, which have been cleverly treated in terms of scale, hierarchy, and perspective to create a warm feeling that is completely different from the traditional hospital conventions.

Daniel Hopkinson

The office and commercial building in Lahore underwent a rigorous analysis of the surrounding area’s colors, materials, and shapes before its design. Four different colors were selected for the exterior curtain walls, with the street-facing side featuring stone and clay in shades of grey, while the opposite side utilized glossy white and grey glaze, offering a more “high-tech” appearance.

Marc Knecht

-05-

Price

The price composition of terracotta wall panel mainly includes terracotta plate, keel and supporting components, labor cost, measures cost and manufacturer’s profit. Among them, the price of plate is generally between 200-300 yuan/m², the keel and its supporting components are between 80-100 yuan/m², and the labor cost is between 120-150 yuan/m². (The above prices are only the prices of ordinary mid-range products in the market. The prices of materials will fluctuate greatly due to different projects, different brands and customization, and are for reference only.)

Due to the high unit price of terracotta panels, they are only suitable for imitating high-priced stones.

Conclusion: Unlike the non-recyclable nature of stone porcelain plates, terracotta panels production uses pure natural clay as raw material, which can be 100% recycled and reused. The recycled and broken terracotta panels can be used for other building materials such as sidewalks and foundations. At the same time, terracotta panels have the advantages of being light and strong, durable, and comply with the pursuit of “green living” by modern people.

LOPO Terracotta Corporation Limited, established in 2002, is a leading manufacturer of high-quality terracotta building materials. Headquartered in Fujian, China, the company provides innovative and sustainable products, including terracotta panels, baguettes, louvers, and bricks. With a commitment to environmental responsibility, quality, and aesthetics, LOPO Terracotta serves architects, designers, and builders worldwide. The company continually invests in research and development to stay at the forefront of the terracotta industry and provide exceptional customer service.