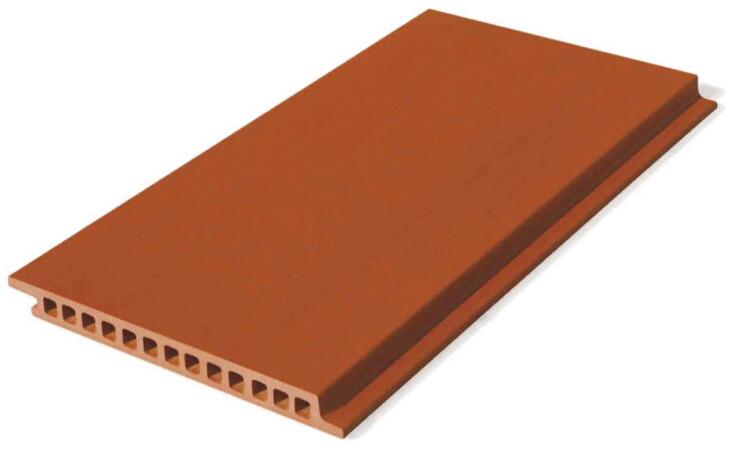

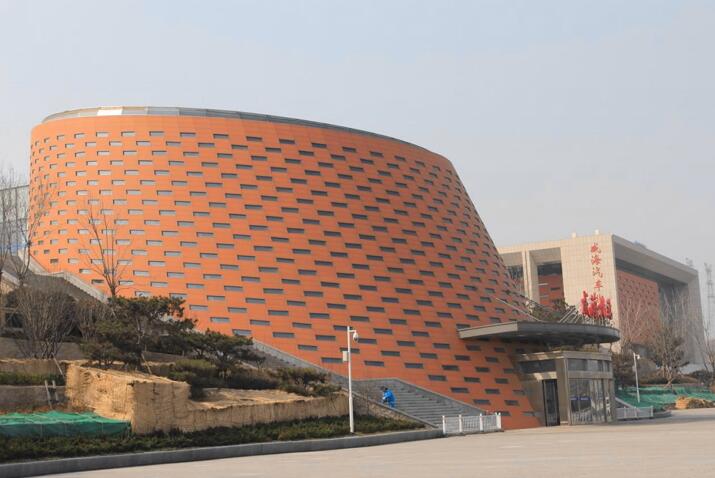

Color is one of the most attractive features of clay and terracotta products. The correct shadow can completely change the appearance of space or building. For this purpose, our company is very strict in quality control, and use integrates colorimeter technology in its production process.

The color of clay and terracotta products may be affected by a variety factors. The traditional color of clay is orange, but if left it in the kiln for a long time, the material will appear red or brown. In order to obtain appearance, an effective color quality control process is required to ensure that each product is perfectly burnt orange.

Colorimeter be used to achieve color quality control. These instruments are capable of detecting small changes in color that the human eyes impossible to see. In addition, the naked eye is subjective when accurately evaluating color samples, as environmental factors and biological limitations can result in changes in color perception between viewers, or even when the same observer objects at different times.

In addition to evaluating glaze and finishing, the kiln firing time is strictly controlled. The color of the product depending on the temperature of kiln and time, it takes for the product to be consumed. This is especially true for terracotta, as its color develops as it is exposed to high temperatures; iron oxidation in the clay deepens the color of the product. Generally, longer time product consumed in the kiln as well as higher temperature, result in darker products. We use the instrument to find the perfect firing time, test clay samples at different temperatures and baking times to find the ideal color temperature.