Terracotta Panel Installation

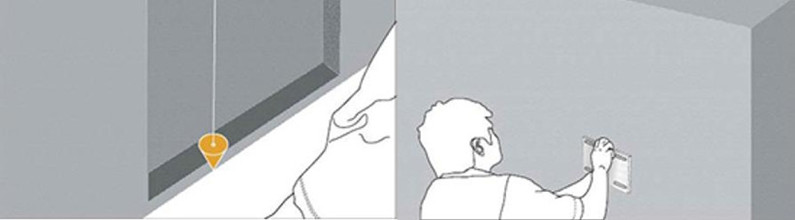

Step 1: Surveying and Setting Out

1.Recheck the civil engineering’s hand-over datum line;

2.Check the indoor elevation of each construction layer, move the indoor elevation line to the outer wall’s working surface, and do deviation measurement of the building outline dimension, to determine the standard line for the drying hanging terracotta panels;

3.Taking the standard line as the benchmark, put the frame lines on the wall according to the arrangement drawing, and mark well;

Step 2: Installation of Corner Connector

1.Hang two installation control lines on the two ends of a signal curtain wall with 0.5~1.2mm steel wires.

2.Determine the corner connector’s installation mark according to the stand column’s installation position. When welding the corner connector, the corner connector’s position should be aligned to the chalk line, and temporarily spot weld the middle corner connector on the same stand column, and check and adjust the verticality of corner connectors on the same stand column; after qualified, full weld the corner connectors and embedded parts; after completion, proceed with the antirust treatment for the welded seams.

Step 3: Installation of Stand Columns

Install the stand columns in place layer by layer from the bottom up; fix the stand aluminum alloy columns on the corner connectors with bolts, and determine the distances between the stand columns and the main body’s wall surface by means of the wall surface end line; adjust the middle stand column’s verticality, and after qualified, spot weld the gaskets, nuts and bolts;

Step 4: Installation of Transverse Beam

When installing the transverse beam, you should snap the line, and ensure firm connection between the stand column and the transverse beam, and the beam spacing should match the height of terracotta panel

Step 5: Installation of Fire Protection Layer Between The Layers

According to the design drawing’s requirements, fix the galvanized steel plate first and then evenly lay fire prevention cotton, and seal the interspace between the galvanized steel plate and the construction structure with fireproof glue.

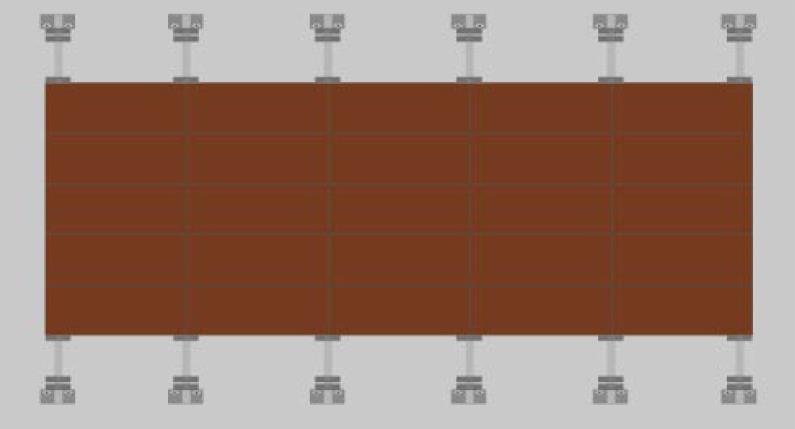

Step 6: Installation of the Terracotta Panel

1.Set on the corner of one curtain wall steel wire plumb line with the upper and bottom ends fixed, and set a vertical steel wire line every 3 to 4 meters in the middle; the construction team installs layer by layer based on the vertical lines, to ensure the curtain wall panel’s verticality to be consistent with the vertical seam size.

2.Install the terracotta panes layer by layer from bottom to top, and in each layer install first the terracotta panel on the corners, and then install the terracotta panels in the middle. When installing the terracotta panels in the bottom row, gradually fill joint sealing glue strips in the vertical seam between two terracotta panels.

3.When installing the terracotta panels, first mount the bottom fasteners on the transverse beam, and each terracotta panel needs at least two fasteners, and place the first row of terracotta panels on the bottom fasteners, and fill joint sealing glue strips between two terracotta panels.

4.Mount the middle fasteners on the transverse beam, on the one hand, to fix the first layer of terracotta panels, on the other hand to provide support for installing the next layer of terracotta panels;

Afterwards, repeat the above-mentioned installation process, and install the top convergent panel at last.

Step 7. Terracotta Panel Cleaning

After installation, the terracotta panel surface should be washed by high pressure water or cleaned with a brush, and it is forbidden to use solvent chemical detergent to clean the terracotta panel;

Quality Assurance Measures

1.According to the width of the building, set up enough vertical and horizontal lines to meet the requirements, to ensure the channel steel skeletons are at the same plane after installation.

2.Fittings and gaskets at the two ends of the transverse beam should be installed in the desired locations on the stand columns, and should be installed firmly, and the joint seam should be tight;

3.The vertical control lines should be checked every day, to avoid cumulative measuring errors, to ensure that the curtain wall surface’s evenness and the panel elevation’s verticality.