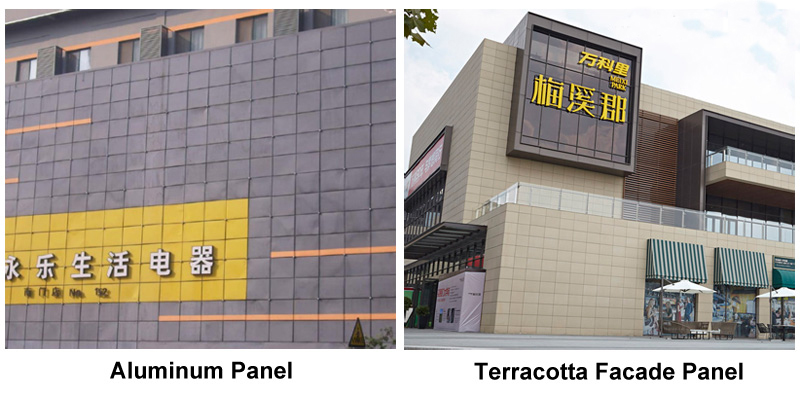

Glass, natural stone, aluminum panel are the most common materials in architectural facade cladding projects application. However, debuted in the late 1980s, terracotta panel is like a rising star in this area. What are the comparable strengths of Terracotta Panel?

Green and Environmental Friendly

Terracotta panels’ raw material is 100% natural clay, and the terracotta facade panel is colored by making use of the clay’s natural color and luster, with very little or no dyeing chemicals added. “Mono color before, but colorful after the kiln firing”, the terracotta panels are with diverse colors, the color and luster are natural and in rich texture, and it will never fade, which well meets the modern architecture’s design demands for mainstream colors. Meanwhile, the products are without any radiation and can be 100% recycled, which are indeed green construction materials friendly to the environment.

Open System, Thermal and Sound Insulated

Terracotta panels have a specific open installation method formed by transverse seam lapping, which is good for protecting the building’s main structure from bad weather and air pollution’s erosion, and can prevent the wall space from deposits to maintain the curtain wall’s beauty; meanwhile, an air layer which can “breathe free” between the surface material and the wall, with the addition of the hollow design of the terracotta panel product itself, can effectively cut off heat conduction and improve the building wall’s acoustic performance, and the whole system has thermal insulation, sound insulation, ventilation, and moisture removing functions, which can effectively improve the indoor temperature environment in sunmmer to eliminate the heat bridge effect and save energy comsumption.

Waterproof and Anti-collision Design, Pressure-proof and Anti-seismic

Terracotta panels are with splicing design for installation based on the Rain Screen Principle, and a special design using EPDM gaskets connecting the parting between interfaces on both ends, can effectively reduce rainwater invasion, prevent terracotta panels’ lateral movement, and prevent the collision between adjacent terracotta panels. Meanwhile, it uses flexible insulation spacers to separate terracotta panels from hanging articles, to separate hanging articles from cross beams, to improve the system’s anti-seismic performance, to avoid electrolytic corrosion between different metal materials, and also to eliminate noise and distortion. The improved terracotta panel system can reach 10 degree anti-seismic performance, especially suitable for architectures having demands for wind resistance and seismic performance.

Excellent Building Performance Index

Terracotta panel products are produced through processes of strict raw material processing, high pressure extrusion forming, and 1,200 ℃ high temperature burning, with very stable and even hemispherical properties. As curtain wall materials, terracotta panels have features of fire safety, acid and alkali resistance, scratch and wear resistance, and high compression strength. Even placed in environments of ultra-high temperature or of low temperature and frost, the terracotta panels can keep great stability performance.

Easy Installation, Quicker Construction Progress

Terracotta panels do not need slotting on the back during construction, and can be installed directly. Meanwhile, the panels can be cut at will, and laid out flexibly, so the terracotta panels can be installed very soon after the curtain wall’s keels are fixed.

Convenient Maintenance

The Tterracotta panel wall cladding surface is anti-static and not easy to adsorb dust. If there is dust on the surface, it is easy to be cleaned after rain wash, so the terracotta panel has a certain feature of self-cleaning, which can reduce the terracotta panel curtain wall’s cleaning and maintenance costs, and to high-rise buildings, this cannot be ignored.

For daily maintenance, if a certain terracotta panel needs to be replaced, we just need to physically damage the broken terracotta panel to singly replace it with a new one, without affecting the whole terracotta panel curtain wall.

LOPO Corporation has been the most professional manufacture in Asia, which has three branch factories manufacturing CE certificated Terracotta Panel, Terracotta Tile & Brick and Artificial Culture Stone. Cooperated with overseas well-known enterprises, LOPO’S products are whidely used in projects all over your worlds. Please visit www.terracotta-panel.com for more details.